Membrane Switch: A Comprehensive Guide to Its Uses and Applications

Membrane Switch: A Comprehensive Guide to Its Uses and Applications

Blog Article

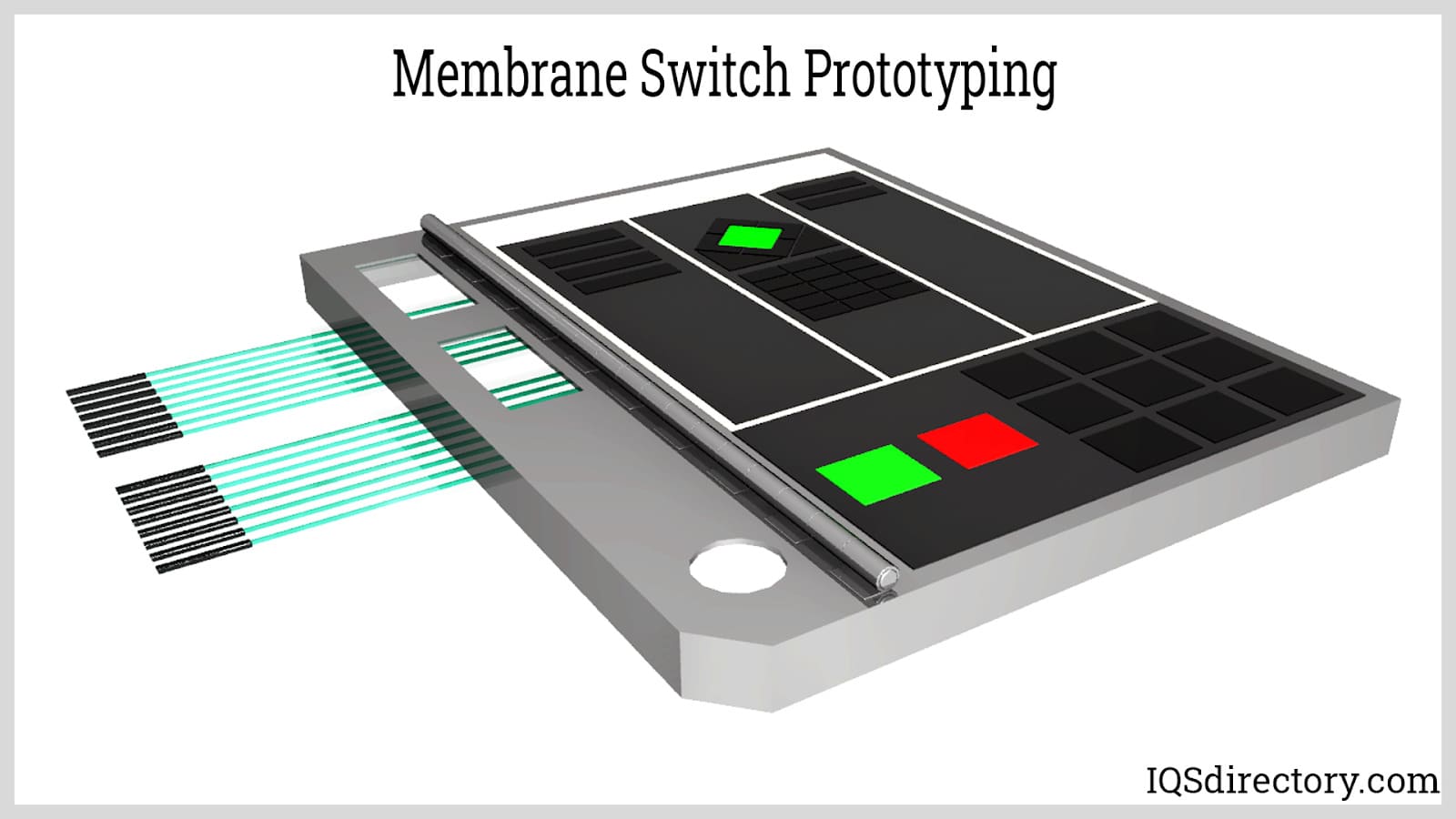

Comprehending Membrane Layer Switches Over: The Secret to Reputable and durable Controls

What Are Membrane Layer Buttons?

Membrane switches are an advanced solution in the realm of individual interface technology, integrating performance and style flawlessly. These tools act as a user interface in between customers and digital systems, integrating numerous elements right into a portable layout. Normally built from versatile, slim layers of materials, membrane layer buttons are developed to react to touch, enabling users to engage with equipment and electronic tools efficiently.

The primary elements of a membrane switch consist of a printed circuit layer, graphic overlay, and a spacer layer that prevents unintended activation. The visuals overlay can be personalized to mirror brand identification or individual choices, improving looks while ensuring use. Membrane layer buttons are generally used in numerous applications, consisting of medical gadgets, consumer electronics, and industrial equipment, owing to their sturdiness and resistance to environmental aspects such as wetness and dirt.

One of the key benefits of membrane layer buttons is their capacity to stand up to deterioration, making them ideal for high-traffic atmospheres. Additionally, they are lightweight and need minimal space, enabling ingenious layouts in product growth. Generally, membrane switches represent a useful and efficient option for modern electronic user interfaces, weding technology with user-centric style principles.

How Membrane Changes Job

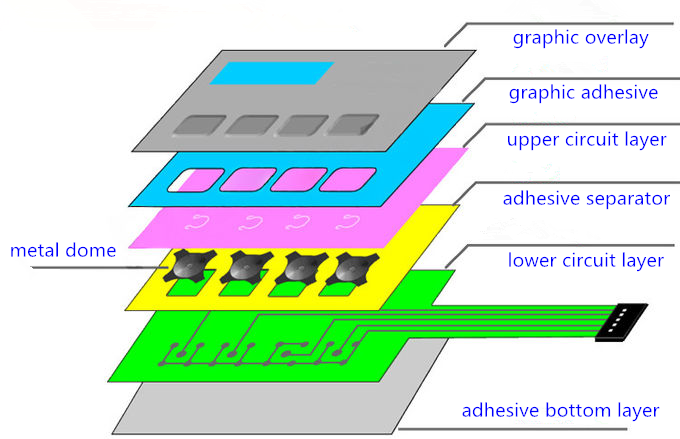

The operation of membrane switches depend upon a simple yet effective system that translates user input into electronic signals. These switches include several layers, usually including a visuals overlay, a spacer layer, and a circuit layer. When a user presses the button, the top layer flaws, allowing a conductive component in the circuit layer to reach a matching conductive pad on the bottom of the visuals overlay. This call closes the circuit and sends an electronic signal to the gadget, suggesting that the button has been triggered.

The layout of membrane layer buttons can differ, but they typically incorporate domes or tactile aspects to give responses to the user, enhancing the total experience - membrane switch. The products used in membrane buttons, such as polyester or polycarbonate, contribute to their longevity and resistance to environmental elements, consisting of wetness and dust. In addition, the published circuits are usually enveloped, which protects them from deterioration with time.

Advantages of Membrane Switches

Additionally, membrane layer buttons are understood for their longevity. Constructed from durable products, they are immune to dirt, moisture, and physical wear, which substantially prolongs their life-span compared to typical mechanical switches. This sturdiness makes them especially suitable for high-traffic environments and applications needing long life.

One more significant advantage is the ease of cleaning and maintenance. The smooth surface area of membrane switches decreases dust build-up and is often unsusceptible spills, making them perfect for setups that need regular sanitization.

In addition, membrane buttons use a streamlined account, causing a thinner style that can be integrated into numerous tools without adding bulk. This function not only boosts the visual appeal however also adds to a much more ergonomic item design.

Applications of Membrane Switches

Straightforward and versatile, membrane layer switches locate applications across a broad array of industries, consisting of clinical devices, customer electronics, and commercial equipment. In the medical area, these switches are important to tools such as diagnostic devices, client monitoring systems, and infusion pumps, where dependability and ease of cleaning are critical. Their capacity to endure harsh environments and maintain functionality makes them suitable for such applications.

In customer electronic devices, membrane layer switches are used in products like microwaves, cleaning devices, and push-button controls - membrane additional reading switch. Their smooth design permits instinctive individual interfaces, boosting the general individual experience while giving longevity and resistance to tear and wear

Commercial equipment likewise benefits from membrane layer buttons, specifically in control panels for machinery and automation systems. These buttons offer protection against dirt and wetness, making certain regular performance in difficult environments. Moreover, their personalized features permit producers to tailor them to specific functional demands, enhancing effectiveness and capability.

Choosing the Right Membrane Switch

When selecting a membrane button, it is vital to think about different variables that affect performance and viability for particular applications. The main factors to consider consist of ecological problems, tactile responses, resilience, and style specs.

First, evaluate the operating setting; buttons revealed to wetness, chemicals, or severe temperature levels call for details materials to make certain longevity and performance. Next off, assess the need for responsive responses. Depending on user interaction, some applications might gain from a responsive action to verify activation, while others might like a non-tactile layout for aesthetic factors.

Longevity is one more important aspect; membrane layer buttons need to be made to hold up against frequent usage, impacts, and abrasion. Make visit our website certain the chosen button can sustain the expected lifecycle, specifically in high-usage situations.

Final Thought

In final thought, membrane layer switches offer as important parts in the style of durable and dependable control systems across various sectors. The convenience of membrane layer switches enables for tailored services that satisfy particular functional requirements, enhancing their importance in modern innovation.

Membrane changes stand for a vital facet of contemporary user interface layout, mixing capability with strength in numerous applications.Membrane layer switches are a sophisticated option in the realm of customer interface technology, combining performance and layout effortlessly. Commonly constructed from adaptable, slim layers of products, membrane switches are designed to respond to touch, allowing customers to engage with machinery and electronic tools continue reading this effectively.

The layout of membrane layer switches can differ, however they often incorporate domes or responsive elements to offer feedback to the user, boosting the total experience.In conclusion, membrane layer switches offer as necessary elements in the layout of reputable and long lasting control systems across various sectors.

Report this page